Thermoplastic sheets are a cornerstone in modern manufacturing and construction, offering a blend of versatility, durability, and cost-efficiency.

These materials, which become pliable when heated and solidify upon cooling, are used across various industries due to their adaptable nature.

From automotive parts and medical devices to packaging materials and construction components, thermoplastic sheets provide essential solutions tailored to meet specific needs.

In this comprehensive guide, we will delve into the different types of thermoplastic sheets, their applications, and the significant benefits they offer.

Types of Thermoplastic Sheets

Polyethylene (PE) Sheets

Polyethylene sheets are known for their toughness and flexibility. They are resistant to chemicals and moisture, making them ideal for applications in packaging, where they can be used for containers and liners. Their high impact strength also sees them used in playground equipment and protective sheathing.

Polypropylene (PP) Sheets

Polypropylene sheets boast a combination of properties such as low density, high chemical resistance, and excellent electrical insulation. They are commonly found in automotive components, food packaging, and medical devices due to their robust nature and safety for direct contact with consumables.

Polyvinyl Chloride (PVC) Sheets

PVC sheets are highly valued for their fire-resistant properties and durability. They are widely used in the construction industry for applications like piping, flooring, and wall coverings. Their ability to withstand harsh environmental conditions makes them a reliable choice for outdoor applications as well.

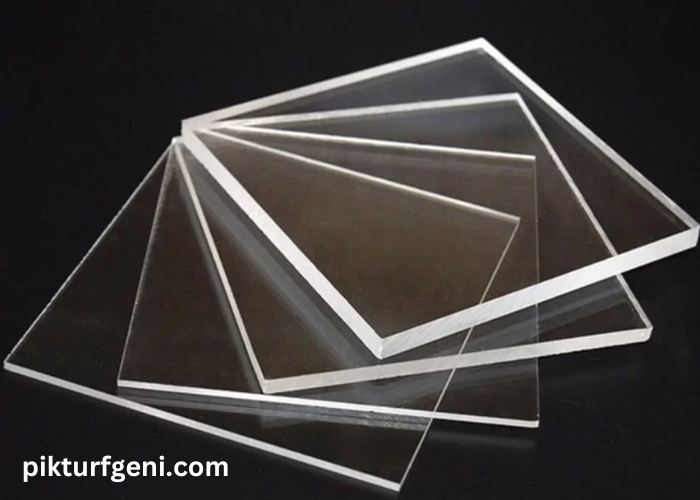

Acrylic Sheets

Acrylic sheets, also known as PMMA (Polymethyl Methacrylate), are famous for their clarity and resistance to weathering. They are often used in applications where transparency and aesthetic appeal are crucial, such as in windows, displays, and signage. You can easily find acrylic sheet cut to size options to fit specific needs, making them highly versatile.

Polycarbonate Sheets

Polycarbonate sheets offer an impressive balance of lightweight and high impact resistance. These sheets are used in safety glasses, skylights, and automotive parts. Their robustness against physical impact and UV radiation ensures longevity and reliability in various demanding environments.

ABS (Acrylonitrile Butadiene Styrene) Sheets

ABS sheets are known for their excellent toughness and impact resistance. They are commonly used in automotive body parts, consumer electronics housings, and LEGO bricks. Their ease of processing and molding makes them a favourite in manufacturing complex shapes and durable components.

Applications of Thermoplastic Sheets

Thermoplastic sheets are utilised across a diverse range of industries due to their adaptability and robust properties.

In the construction sector, they serve as essential components in roofing, flooring, and insulation, providing durability and ease of installation.

The automotive industry benefits from their use in manufacturing both interior and exterior parts, ensuring vehicles are lightweight yet sturdy.

Packaging relies on these sheets for creating safe, moisture-resistant containers, while the medical field uses them to produce reliable, sterilizable devices and equipment.

Benefits of Using Thermoplastic Sheets

Thermoplastic sheets offer a multitude of benefits, making them a preferred choice across various industries.

Their exceptional durability and strength ensure long-lasting performance, while their lightweight nature facilitates easy handling, transportation, and installation.

The versatility of thermoplastic sheets allows them to be molded and shaped to meet specific requirements, enhancing their application range.

They are cost-effective, providing significant long-term savings due to their low maintenance needs and reusability.